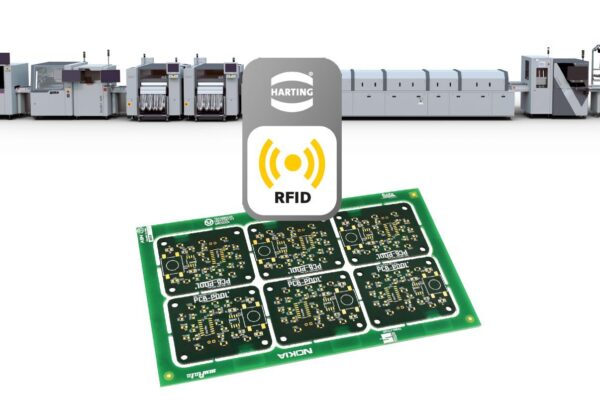

SMT production line detects PCBs using RFID

Based on the company’s RFID-4-SMT auto-ID solution, the new system cuts error rates, radically simplifies documentation requirements and forms the basis for automated PCB production in a batch size of 1. When the PCB is first produced, a small UHF RFID chip is inserted in the blank or attached as a component later on. From this point, manufacturing data can be written to and read from the RFID chip at each station in the manufacturing process. Even unplanned events such as machine malfunctions can be stored. The reader and antenna can easily be integrated into both new and old systems. The compact design and IP67 protection class also facilitate upgrading. Full data integration in the manufacturing system is therefore made possible – but not absolutely necessary – at any time.

Thanks to the modular and open software architecture of the Ha-VIS RF-R350 UHF RFID read-write device, data can be pre-processed in the reader. The data is stored in line with ISO standards and the GS1 standards applied to commercial goods transport. This applies not only for the ID of the PCB itself, but also for the processing nd manufacturing data stored in the user memory of the RFID chip. This data is all transparent and can thus easily be used later by a third party. Once the UHF RFID technology has been fitted on the PCB, it can be used throughout the lifetime of the PCB. It is possible for several PCBs to be read in bulk without optical contact: for example, through foil and cardboard packaging, which makes the technology eminently suitable for warehouse and logistics processes.

Harting – www.harting.com

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News